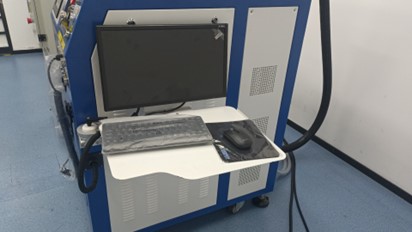

YAG pulse automatic laser welding machine is an efficient and high-quality welding equipment. It adopts pulse laser technology and has high-precision and high-speed welding capabilities. It is suitable for precision welding of various metal materials and is widely used in electronics, communications, automobiles, medical devices and other fields.

YAG pulse automatic laser welding machine is mainly composed of the following parts:

1. Laser: generates pulse laser and is the core component of the welding machine.

2. Welding head: transmits laser to the welding area, usually equipped with focusing and optical path adjustment system.

3. Control system: controls the pulse frequency, power, delay and other parameters of the laser, as well as the motion trajectory of the workbench.

4. Cooling system: provides cooling water for the laser and welding head to ensure its normal operation5. Auxiliary components: including workbench, protective cover, observation window, etc.

Equipment maintenance

1. Regularly check the working status of each component of the equipment to ensure normal operation. Pay special attention to key components such as lasers, cooling systems and water pipes.

2. Clean the surface and internal components of the equipment regularly to keep the equipment clean. Be careful to avoid water or other liquids from entering the internal circuit or optical components when cleaning.

3. Replace consumables such as filter elements, seals, etc. as needed. Make sure to use original or compatible consumables to extend the service life of the equipment.

4. If the equipment has not been used for a long time or has been out of service for a long time, it should be turned on regularly for inspection and necessary maintenance operations to avoid equipment damage or performance degradation.

5. Before performing maintenance, be sure to disconnect the power supply of the equipment and turn off the water supply, and ensure that the workbench is in a safe position to prevent accidents. Non-professionals are not allowed to perform internal repairs or replace key components without authorization. If necessary, please contact professional maintenance personnel for maintenance.

Common problems and solutions when using equipment

Q1: The laser cannot be started or the output power is insufficient.

Check whether the power supply and water pipe connections are normal; check whether the laser is working properly; A1: If there is a problem, please contact professional technicians for repair and replacement.

Q2: The weld quality is unstable or the weld width is uneven during welding A2: Check whether the parameter settings are correct; check whether the workbench movement trajectory is accurate; check whether the workpiece placement is stable: adjust the relevant parameters to optimize the welding effect.

Q3: The cooling system makes abnormal sounds or the cooling water temperature is too high A3: Check whether the cooling water is sufficient; Check whether the water pipe connection is firm: Clean the radiator or replace the cooling water; If there is any problem, please contact professional technicians for inspection and repair Q4: The workbench moves unsteadily or the positioning accuracy decreases

A4: Check whether the motor and transmission parts are normal; Clean and lubricate the moving parts: Recalibrate the workbench positioning system: If there is any problem, please contact professional technicians for inspection and repair.

Post time: Aug-19-2024