I believe that some customers who purchase fiber laser cutting machines may not be very clear about the principles of laser cutting machines. Now DOWIN will explain to you the basic principles of fiber laser cutting machines.

1. Principle of laser cutting

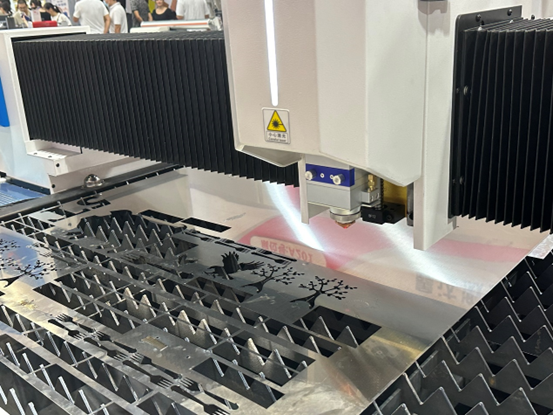

The laser beam is focused into a very small spot, so that the spot reaches a very high-power density. The material under the spot is quickly heated to the vaporization temperature, evaporates to form holes, and moves relative to the material at the speed of light, making the holes continuous and forming a very narrow slit.

2. Characteristics of laser cutting

a: Good cutting quality. Due to the small laser spot and high energy density, a laser cutting can achieve good cutting quality. The slit of laser cutting is generally 0.1-0.2mm, the width of the heat-affected zone is very small, the geometry of the slit is good, and the cross section of the slit is a relatively regular rectangle. The cutting surface of laser cutting is burr-free, and the surface roughness R can generally reach more than 12.5um. Laser cutting can even be used as the last processing step. The cutting surface generally does not need to be processed again and can be directly welded, and the parts can be used directly.

b: Fast cutting speed. Laser cutting is relatively fast. For example, with a 2000W laser power, the cutting speed of 8mm thick carbon steel is 1.6m/min, and the cutting speed of 2mm thick stainless steel is 5.5m/min. Because the heat-affected zone of the workpiece is small and the deformation is minimal during laser cutting, it does not require clamping and fixing, which can save clamping fixtures and auxiliary time such as clamping.

c: There are many types of materials that can be cut. Compared with cutting methods such as oxygen-ethane cutting and plasma cutting, laser cutting can cut more types of materials, including metals, non-metals, metal-based and non-metal-based composite materials, etc. Different materials have different laser cutting adaptability due to their own different absorption rates of lasers.

d: Suitable for processing large products. The mold manufacturing cost of large products is very high. Laser processing does not require any molds, and laser processing completely avoids the collapse of the edge formed during material punching and shearing, which can greatly reduce the production cost of the enterprise and improve the grade of the product.

e: Clean, safe and pollution-free. The laser cutting process has low noise, small vibration and no pollution, which greatly improves the working environment of the operator.

f: Not susceptible to electromagnetic interference. Unlike electron beam processing, laser processing is not sensitive to electromagnetic interference and does not require a vacuum environment.

The above is the relevant content sorted out for everyone. If you want to know more about fiber laser cutting machines, you can follow us. We will update relevant information about fiber laser cutting machines from time to time. Or you can also contact us, we will send the details what you want to know.

Post time: Jul-19-2024