How to Cut A Long Piece of Cloth?

With the improvement of people's living standards, people's pursuit of personalization and fashion is also changing. A perfect machine plays an important role. A CCD carbon dioxide cloth cutting machine can meet people's rapidly changing aesthetic needs.

Advantages of CCD carbon dioxide cloth cutting machine:

Improve production efficiency

For example, in various clothing and luggage fabric manufacturing factories, traditional manual cutting may take hours to complete the task, but the cloth cutting machine can complete it in a few minutes, greatly shortening the factory's production cycle.

Ensure cutting accuracy

Accurate cutting can ensure that the size and shape of each piece of cloth meet the design requirements. For example, when making fabrics with different patterns, accurate fabric cutting can achieve perfect splicing of each component.

Save materials

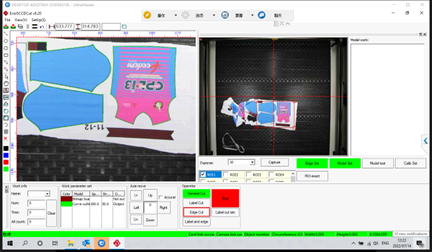

The fabric cutting machine with CCD automatic identification system is equipped with an intelligent control system, which can automatically identify the pattern to be cut and automatically layout and plan the cutting path, which can maximize the use of fabrics and reduce the generation of waste.

How does the CCD automatic feeding cutting machine cut a whole piece of cloth?

Question from a customer?A very friendly customer needed to cut six meters of fabric

According to the needs of customers, explain to customers how to cut a complete piece of fabric using a fabric cutting machine.

First of all, the automatic feeding has a splicing and cutting function, so you only need to set the machine's working mode to splicing and cutting mode in the software. After selecting this mode, this mode will divide a piece of fabric with a width of 1.5 meters and a length of 6 meters into 6 small pieces with a width of 1.5 meters and a length of 1 meter, until the complete picture of the 6-meter-long fabric is spliced and cut out.

There are also some disadvantages of fabric cutting machines:

1. High equipment cost

Especially high-precision, high-performance fabric cutting machines are relatively expensive. For some small businesses or self-employed operators, it may be a large investment. For example, an advanced laser fabric cutting machine may require hundreds of thousands or even millions of dollars.

2. High maintenance and repair costs

Complex mechanical and electronic components require regular maintenance and care to ensure their normal operation.

Once a failure occurs, the repair cost may be high and professional technicians are required to repair it. For example, replacing key components or performing precision calibration may cost a lot. Choose a cost-effective carbon dioxide fabric cutting machine

How to choose a cost-effective CO2 laser fabric cutting machine:

1. A professional laser equipment supplier will escort your purchase, and they are usually more guaranteed in quality control and after-sales service.

2. After-sales service: Make sure your supplier provides good after-sales service, including training, maintenance and technical support. Timely after-sales support is essential to ensure the normal operation of the machine.

3. Clear requirements: Determine the type, thickness and size of fabric you need to cut, as well as the required cutting accuracy and speed. This will help you choose the right machine model and configuration.