Automatic Fiber Laser Welding Machine Application for Battery Industry

Laser welding is one of the most promising joining technologies for EV batteries and energy storage systems. It provides the speed and precision needed to make the thousands of welds that connect tabs and busbars in battery packs, modules, and cells.

All types of battery cells can be laser welded, including cylindrical cells, prismatic cells, and pouch cells. Laser welding is being implemented for a wide range of electric battery applications:

Electric vehicles (cars, taxis, etc.)

Electric commercial vehicles (forklifts, trucks, buses, airplanes, ships, etc.)

Recreational electric vehicles (motorcycles, bicycles, four wheelers, jet skis, boats, etc.)

Energy storage systems

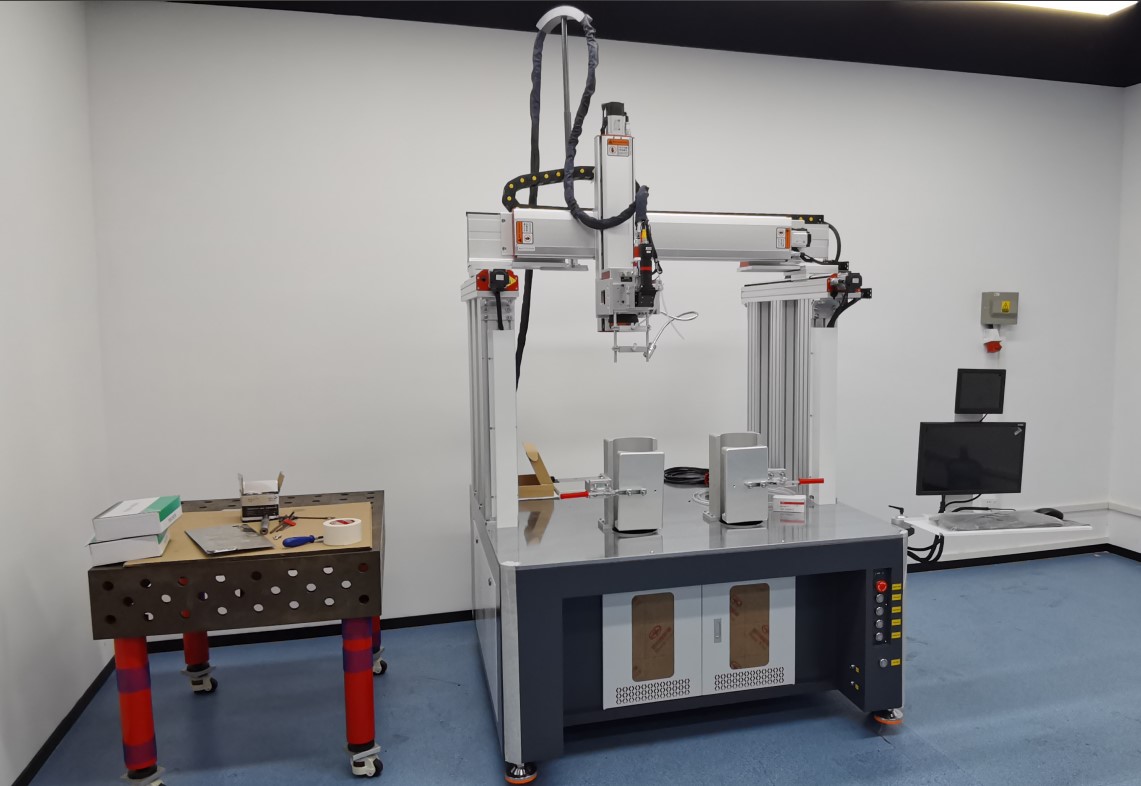

Features of our machine

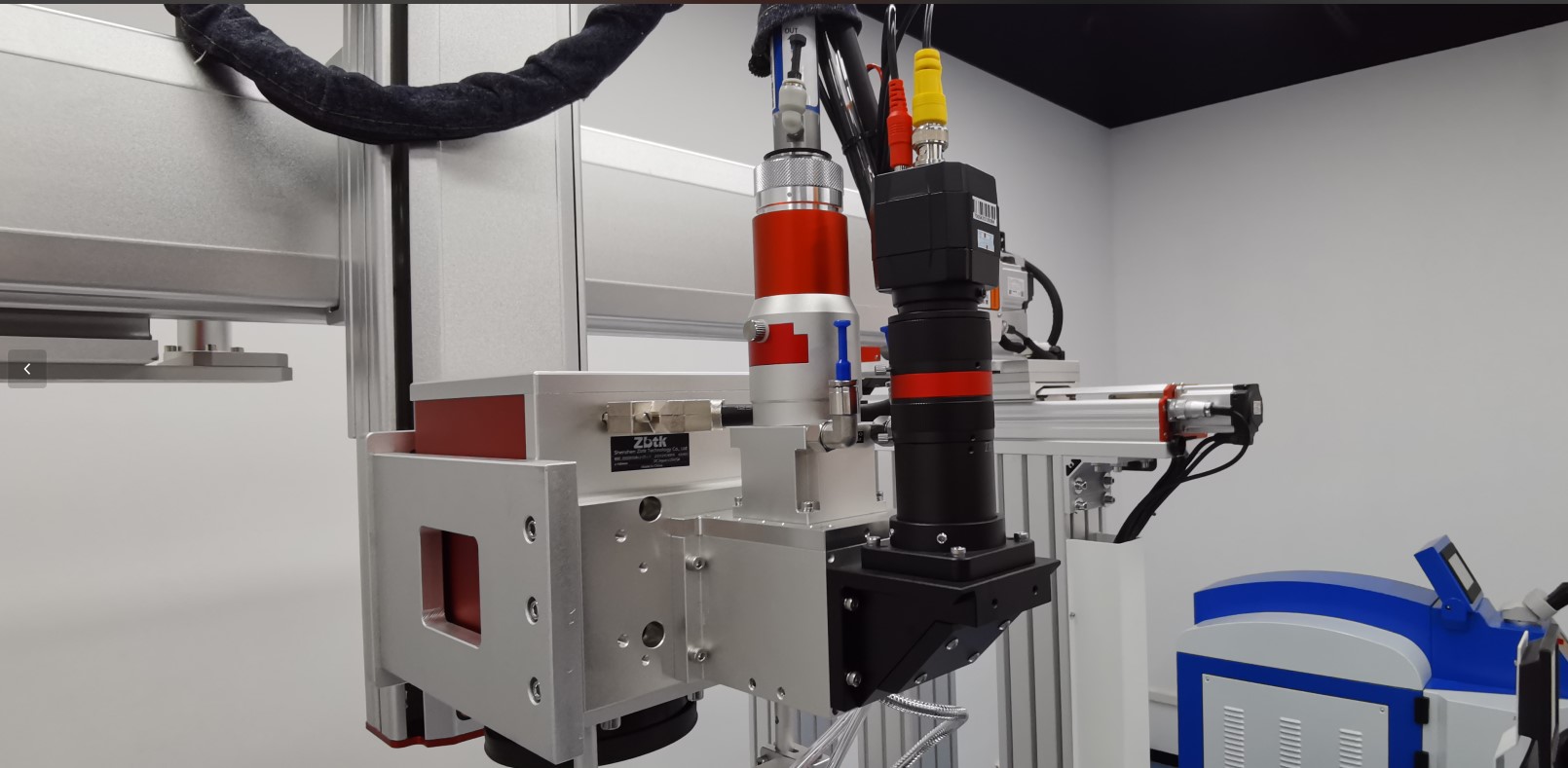

FEATURE 1 :

Double swing laser welding joint

It can be used for continuous precision laser welding and laser spot welding, with high welding strength, high precision and fast speed.

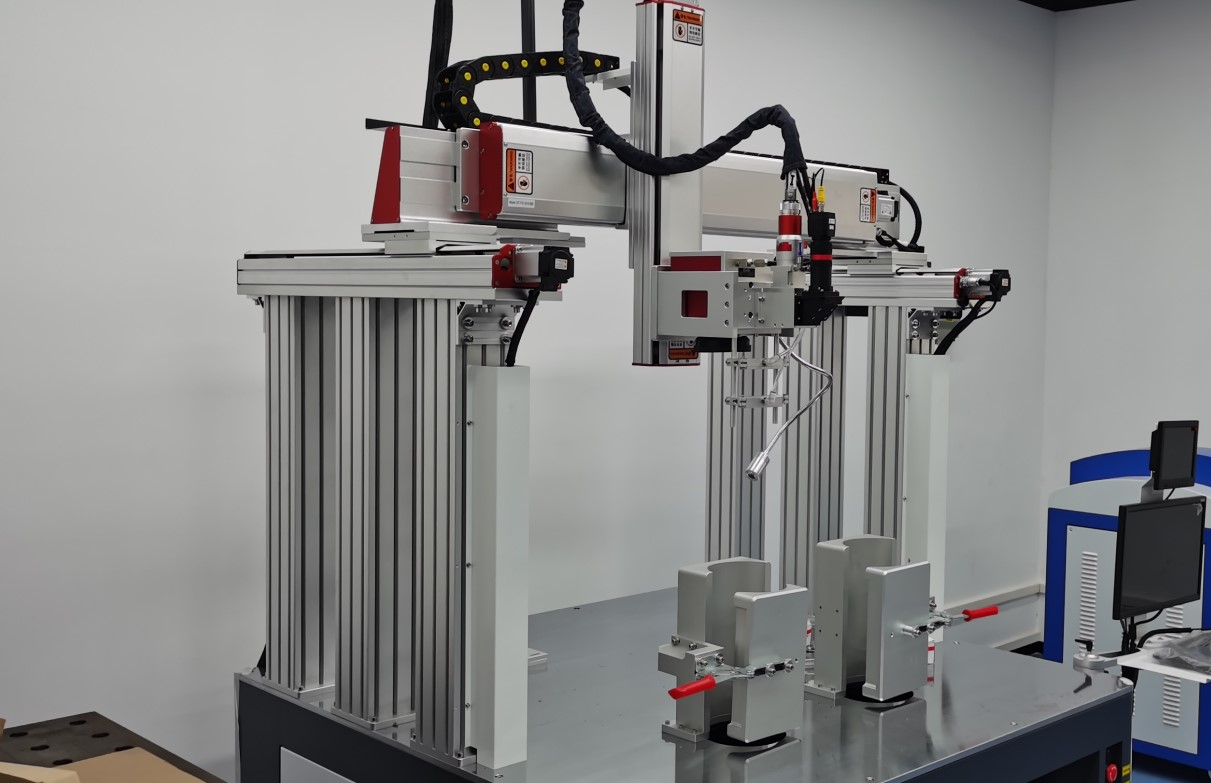

FEATURE 2

CNC three-way mobile station (XYZ)

Computer program control, geometric space movement, adapt to the shape and size of most products,Any welding path (arc, semicircle)

FEATURE 3

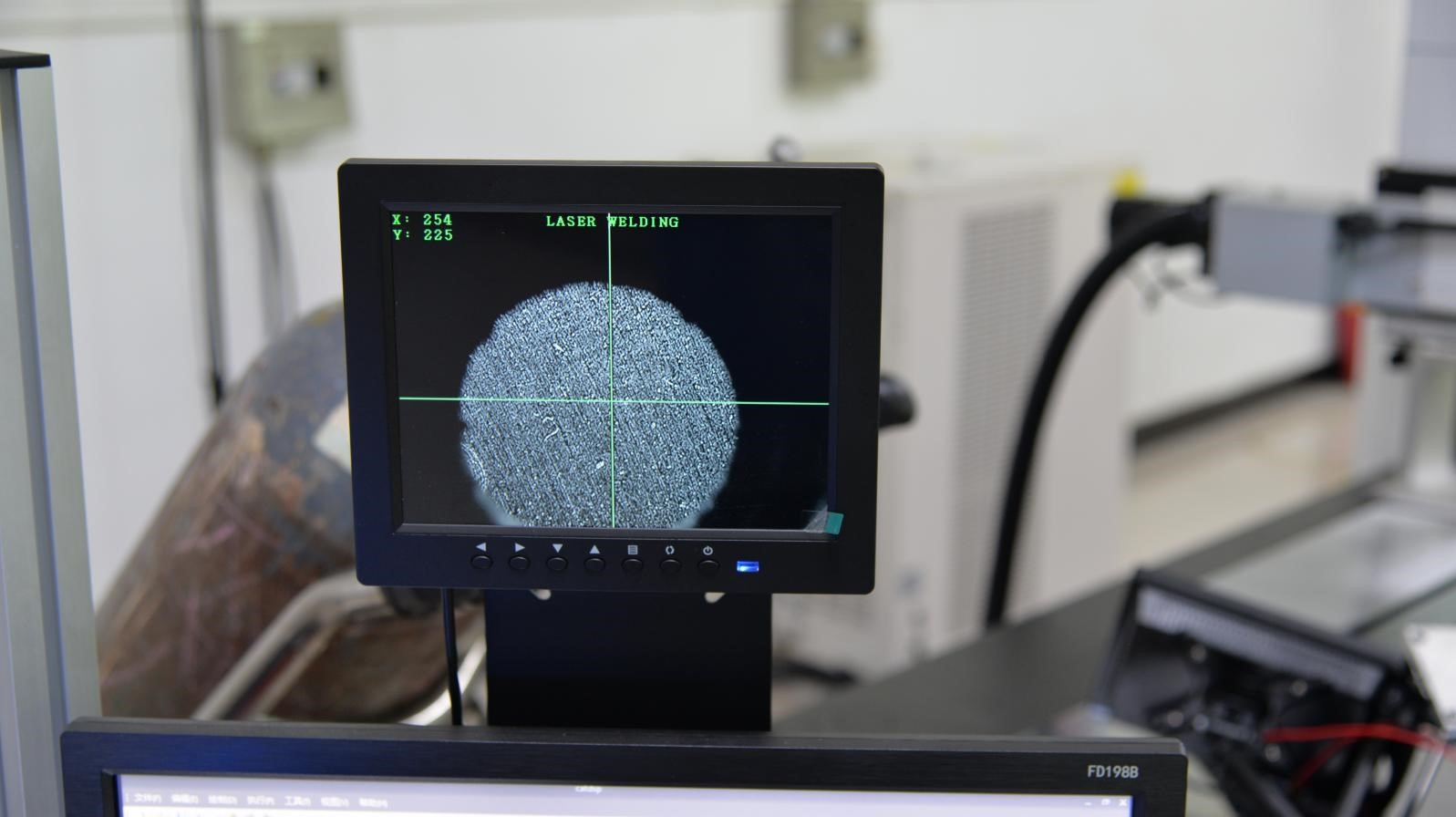

1,X, Y, Z electric three-axis stroke 400*300*300, it can reach repeat positioning accuracy ±0.05;

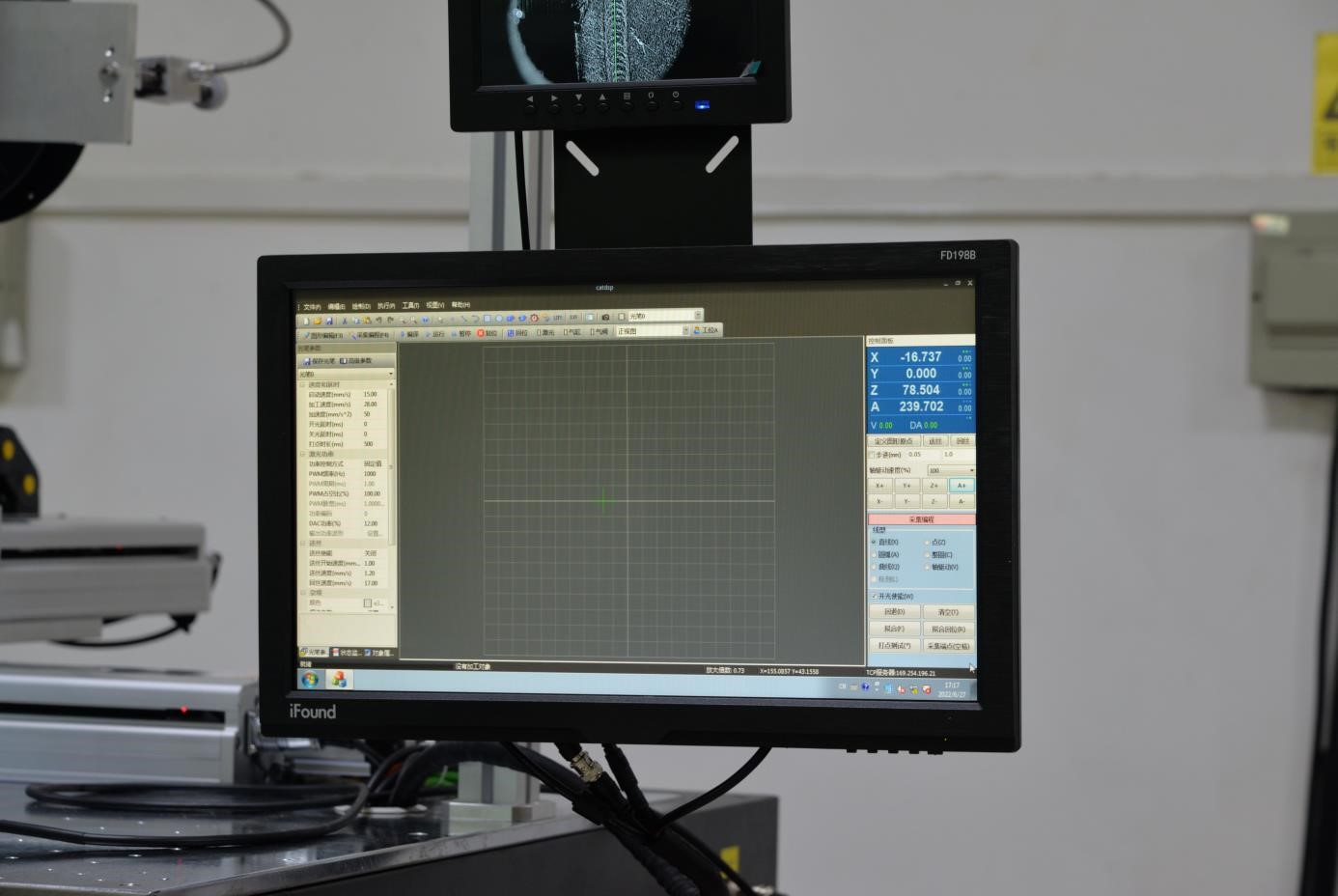

2,It adopts industrial PC control professional software which is easy to operate;

3,The standard 8-inch monitor is equipped with a high-speed vibrating lens; the vibrating lens can be equipped with CCD coaxial monitoring, which is convenient

for observing the welding effect;

4,Optional laser generator, such as YAG, QCW high-speed splitter, fiber laser, semiconductor, etc.

5,Exclusive models can be customized according to customer needs, and two rotating shafts can be added.

Compared with other laser welding device , advantages of automatic fiber laser battery welding machine

1 . with big working area , support big size like car battery etc welding , also can used for many different types of lithium battery pack

2. Good processing quality, small laser welding spots, small taper, high accuracy, flat welding surface without air bubbles

3. High processing efficiency, fast welding machine speed, improve work efficiency by 3-5 times

4. Widely application , for example square aluminum -shell power battery set, composition power battery pack, cylindrical power battery pack, large monomer nickel, welded thread, large polymer ear nickel and other batteries

5.variety of operating modes, point welding, connecting welding, stacking welding, sealing welding, etc.

6.Industrial PC control can perform round welding processing arbitrarily composed of planes such as laser spots, straight lines, circles, squares and other planes